Top Tips to Lower Your High Energy Bills During Summer

April 12, 2018

Dock Solutions

April 17, 2018

Conveyors & Conveyor Systems

The most cost-effective and simplest conveying solution. A proven product which is highly configurable, easy to install and requires only low maintenance. The modular design ensures that manufacturing costs are kept to a minimum.

Different Types of Conveyors & Conveyor Systems

Roller Conveyors |

|---|

The most versatile and economical powered conveyor available. Ideal for straight long runs or complex configurations. Fewer drives are required compared to conventional equipment. Another unique advantage of Lineshaft Conveyors is the number of ancillary modules which can be driven from one motor by means of couplings and universal joints. Available in powder coated steel as standard also available in aluminium and stainless steel.

Chain Transfer Unit

Switch Sorter

Vertical Blade Stop

30° Merge Unit

Roller Turntable

Single Chain Transfer

Bash Plates and End Loading Side Guards

Spiral Conveyors |

|---|

The JP Spiral Belt Conveyor is designed for hygienic conveying of packed or unpacked products. The rigid construction and the strong hybrid belt allow high capacity conveying. This makes the conveyor ideal for highly demanding food-processing industries. The flat belt surface is suitable for variety of loads. The conveyor belt combines plastic panels with stainless-steel rods. This design provides a very smooth and efficient conveying surface.

Superior Product Handling

Optimize floor capacity

Long tracks and fewer transfers

Easy Access for Maintenance

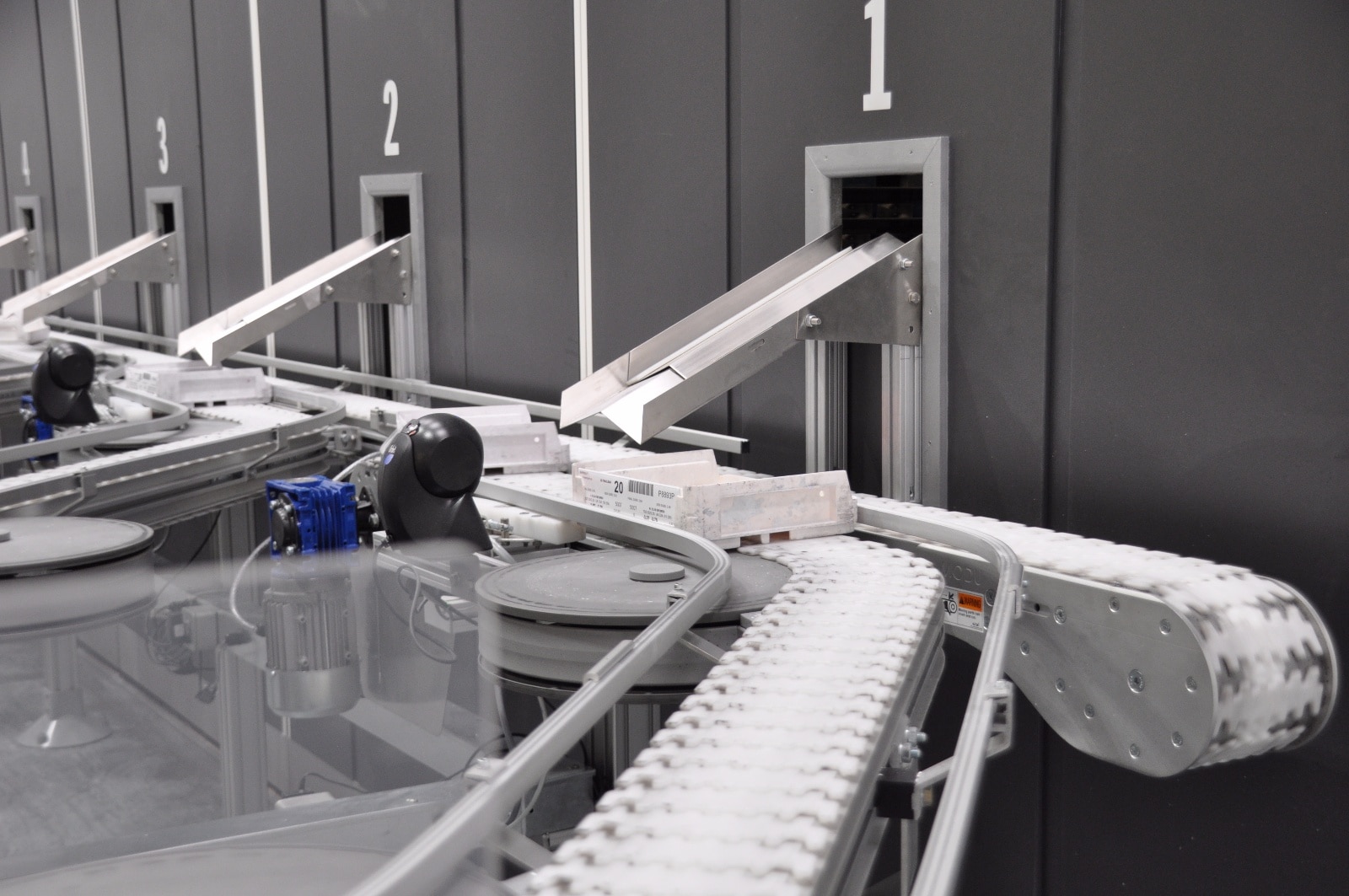

Sortation Systems |

|---|

Sortation systems are often designed to meet the growing demand for smaller order sizes, increased shipping accuracy, and more frequent shipments while improving efficiency in your distribution operations. Sortation is an ideal solution for separating products from in-feed conveyor lines to shipping lanes, palletizing operations, packing stations & other sortation applications. These systems are versatile and can sort a wide range of product sizes and weights to multiple divert lanes.

Sortation is the process of inducting and separating products to specific destination lanes with the purpose of arranging product for a better means of distribution in order to increase productivity. Sortation systems are often employed when high quantities of products need to flow to different destinations for further processing or shipping.

Sorters are the ideal solution for separating products from in-feed conveyor lines to shipping lanes, palletizing operations, packing stations & other sortation applications. Sorters are versatile and can sort a wide range of product sizes and weights to multiple divert lanes.

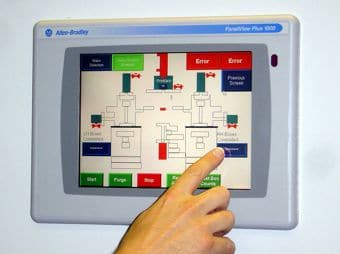

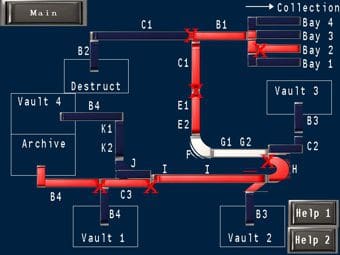

Control Systems |

|---|

Conveyors come complete with purpose builds control systems, and we carry out the full mechanical, electrical, pneumatic and software setup. Controls range from a single motor up to a full control system with HMI touch screen, line mimic and bar code system.

The control panel will be designed to suit the line. Rockwell Allen Bradley PLC’s are used as standard, but if customers have specific requirements then we will use Siemens, Mitsubishi or other leading manufacturers.

Cable routing and piping around the system will be finished to a high standard, to give a clean appearance to the system. Systems can be fully labelled and we will always work to the customer’s specific requirements when required.

Our distribution software can manage the conveying of products along predefined routes to selected machinery. This enables you to move product accurately and cost effectively through your factory. Machines will be kept fed with work without the need for operators to manually feed them. This reduces machine idle times and production costs. Conveyors can stop and start automatically, queues of products can be controlled. If a machine is out of action for maintenance there can be options to route product to other areas. Our system can communicate with barcode readers and other machine control systems.

The most cost-effective and simplest conveying solution […]