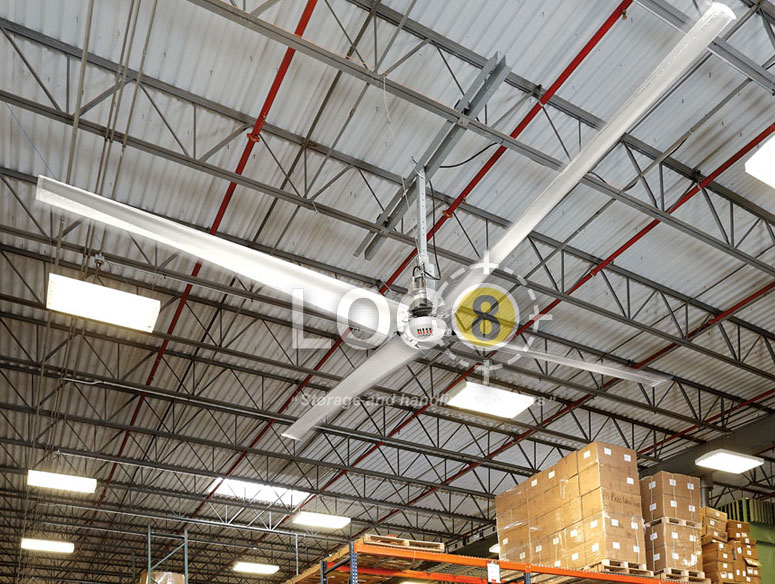

Industrial Fans

April 24, 2020

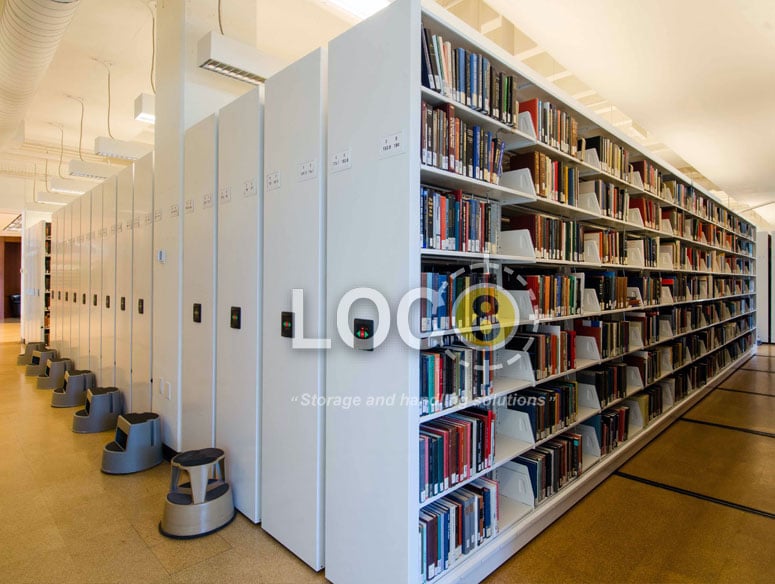

Mobile Shelving

April 26, 2020

Racking

Giving you 100% accessibility to all pallets, first in first out principle and extremely dense storage, Racking can be the ideal space saving solution. Using 50% of warehouse space compared to conventional racking this can produce significant build cost savings. Particularly cost effective for a cold store environment..

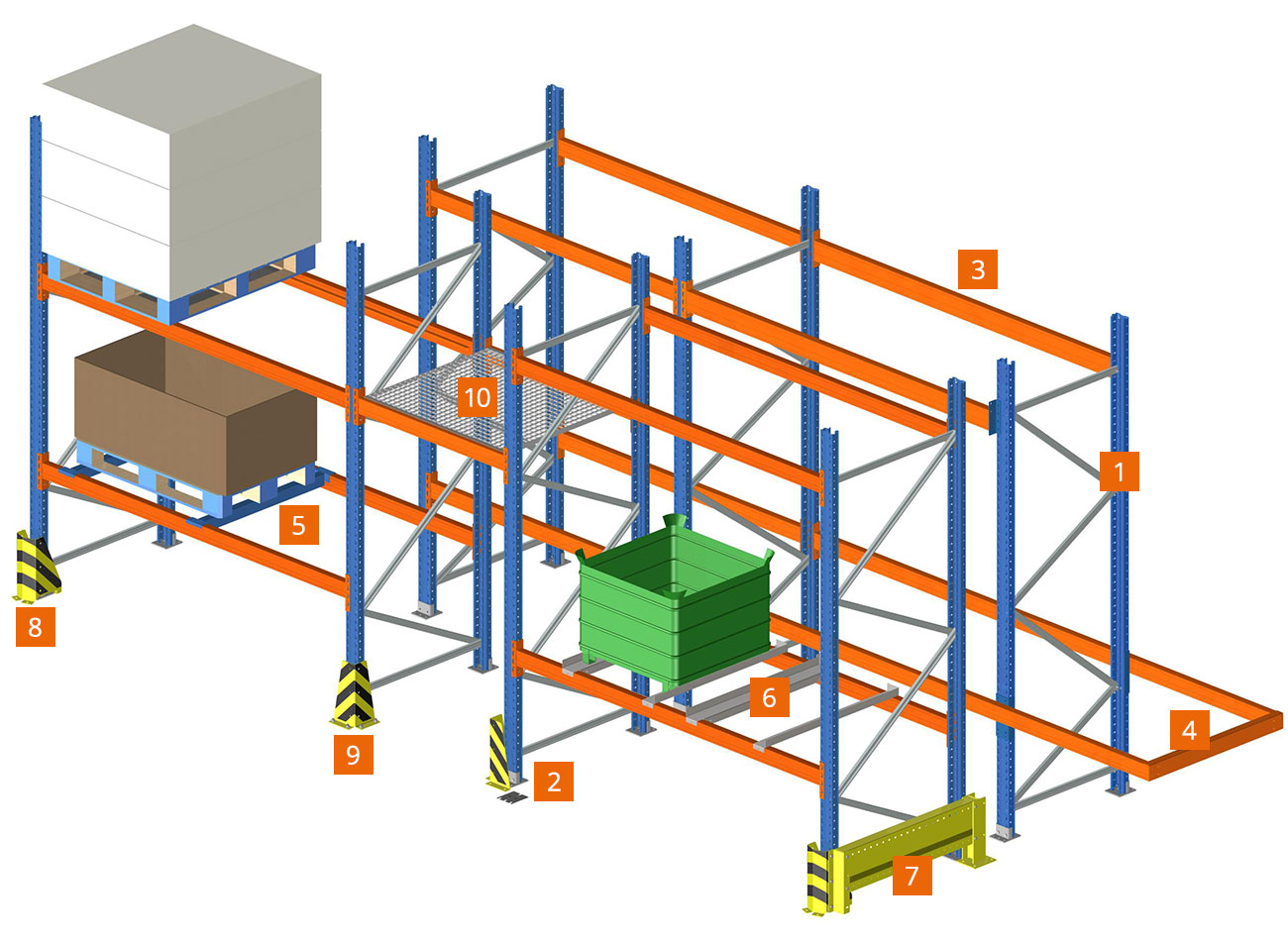

Different Types of Racking

Conventional Pallet Racking |

|---|

Conventional pallet racking system consists of a full range of basic components and accessories to fulfill all of your requirements. The system is designed for the optimized storage of goods of all sizes and weights. All components have been thoroughly tested in specialized laboratories to determine their mechanical properties. These are used to calculate the safe load capacity of each component and ensure that they meet the stringent requirements of the FEM (Fédération Européenne de la Manutention) code for pallet racking.

The Frames

Cantilever Racks & Vertical Storage |

|---|

Cantilever racking is ideal for those applications where you need to store long or bulky product horizontally. Cantilever racking has no front uprights to interfere with the placement or retrieval of loads. Any load or storage level is immediately available. It lowers your handling cost saving you time and money.

Safe and economical storage of long products

Maximises the usage of your floor space and height available

-

Each bar rack is designed to suit your individual requirements

-

Robust racking design to cope with arduous environmentsv

Ideal for plywood, chipboard & timber sheets, plasterboard, building materials, pipe & tubing, sheet steel, roll goods, extrusions etc

Safe and economical storage of long products

Maximises the usage of your floor space and height available

Each bar rack is designed to suit your individual requirements

Robust racking design to cope with arduous environmentsv

Live Storage System |

|---|

LOC8 Live storage system provides efficient and ultra dense storage of palliated goods. The goods are inserted at the on-load face and travel down under the force of gravity. At the off-load face the pallets can be removed. With this system pallets are stored on the fi rst-in/ fi rst-out principle (FIFO).

The Push back system, also realised with roller tracks, provides a last-in/ fi rst-out operation (LIFO). In this case the pallets are loaded and unloaded from the same side. The lift truck pushes the pallets into their storage location and they return under the force of gravity.

Mobile Pallet Racking |

|---|

The Mobile racking system is composed of Conventional pallet racking installed on mobile bases, allowing opening and closing of the aisles. Where compact storage is needed whilst keeping a high degree of accessibility to the stored products, mobile racking may be the best solution, especially where storage space is expensive, for example in coldstores.

The mobiles are operated manually or automatically by means of an integrated RF-system. The PLC-software may be adapted to the client’s specifi c needs or linked to the client’s mainframe.

Safety is guaranteed by a photoelectric beam system, mounted on each mobile rack and in front of the complete installation complying with the European machine safety directives. Adding P&D-locations may further increase the warehouse efficiency, resulting in a higher return on investment.

Open Face Racking |

|---|

Open face racking is particularly suitable for storage of containers and pallets. As box containers are only supported in their four corners a safe storage in conventional pallet racking is not possible. In Open face racking the containers or pallets are stored on depth supports, which are hooked in the side perforations of the frames.

This type of racking provides maximum height utilization by eliminating the horizontal beams as in Conventional pallet racking. The boltless height adjustment every 25 mm allows an optimized partitioning of the storage levels.

Adding some specific construction elements, such as top-ties, top-rail and run-outs, the system can be serviced automatically by AS/RS-cranes.

Drive-in Racking |

|---|

Drive-in racks are designed for storing large quantities of similar pallets and increase the storage space utilisation compared to conventional pallet racking systems. This is achieved by eliminating picking aisles. The system provides safe block stacking of goods, which are too fragile or unstable to be stacked one on top of the other.

High Bay Pallet Racking |

|---|

Pallet racking serviced by cranes requires special arrangements for tolerances in manufacturing and erection. Perfect positioning and levelling are vital for such installations. The cranes are running on a floor mounted rail and stabilised at the top of the mast by a top guide rail. The pallets can be placed “single deep” or “double deep”.

-

Crane height: distance from highest point of the floor to the top-tie

-

Height of the bottom level and the top-level

-

Crane aisle width: distance between the front of opposite pallets

-

Design of the run-outs at both ends of the aisle

-

Type of top rail and its fixation

-

Crane horizontal forces in z- and x-directionss

Crane height: distance from highest point of the floor to the top-tie

Height of the bottom level and the top-level

Crane aisle width: distance between the front of opposite pallets

Design of the run-outs at both ends of the aisle

Type of top rail and its fixation

Crane horizontal forces in z- and x-directionss

Giving you 100% accessibility to all pallets, first in first out [….]